THE COMPANY

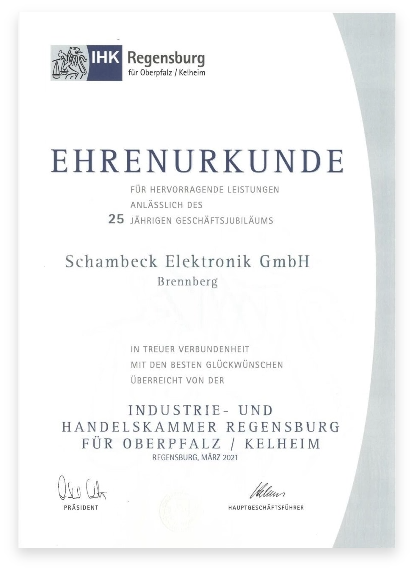

About Schambeck Elektronik GmbH

Schambeck Elektronik GmbH is a medium-sized company in Brennberg, near Regensburg, which specializes in electronics. Our services include cable assembly, conventional assembly, repairs and additions, with a focus on SMD assembly of printed circuit boards. We also offer our high-quality electronics services to customers in Munich.

We combine many years of experience with state-of-the-art technology, including automatic placement machines, to ensure precise placement of small and sensitive components. With our microplacer, we can assemble flip chips, BGAs and micro BGAs of any size.

Our Cube.460 selective soldering system enables high-quality soldering of all THT components, regardless of the quantity. We also take care of material procurement to save you time.

From prototype production and pre-series through to small and large series production, we provide you with comprehensive support.

We are at your side from prototype production through pre-series to the production of small and large series.

State-of-the-art production technologies

Our services for Munich

CONTACT NOW